Anti-X cabins made with a supporting structure in honeycomb hardwood with interposed calibrated and brushed lead sheet.

- For command areas or partitions;

- Plastic laminate coating on both sides, white color (other colors on request);

- Complete with fixing material and aluminum finishing trims;

- Panel dimensions cm 50 x 220h;

- Prepared for the insertion of anti-X swing and sliding doors, and windows of any size.

Protection degrees

The degree of the protection, and therefore the thickness of the lead within the cabin, can vary according to the needs of the customer, who will only be able to indicate it following a consultation with a Qualified Expert. The most common protection degrees for this type of product are Pb mm 1, Pb mm 2, Pb mm 3.

Laminate coating

The PRINT HPL laminate (High-pressure decorative laminates) identifies the high-pressure decorative laminate, a panel consisting of layers of cellulose fibers impregnated with thermosetting resins subjected to a high pressure process consisting in the simultaneous application of heat and pressure. This determines the fluidization and contextual polycondensation of the resins from which a homogeneous, non-porous material with the required surface finish is obtained. Essentially 60% of the HPL laminate consists of paper, while the remaining 40% consists of thermosetting resins (phenolic resin for the internal layers and melamine resin for the surface layer(s)).

The PRINT HPL laminate is also available in the slow flame propagation version (called “F1”) which thanks to the particular composition – in any case halogen-free – guarantees an even higher reaction to fire performance than the standard version.

The plastic laminate coating offers a wide variety of colors available.

The standard color is Bianco Primavera (Spring White).

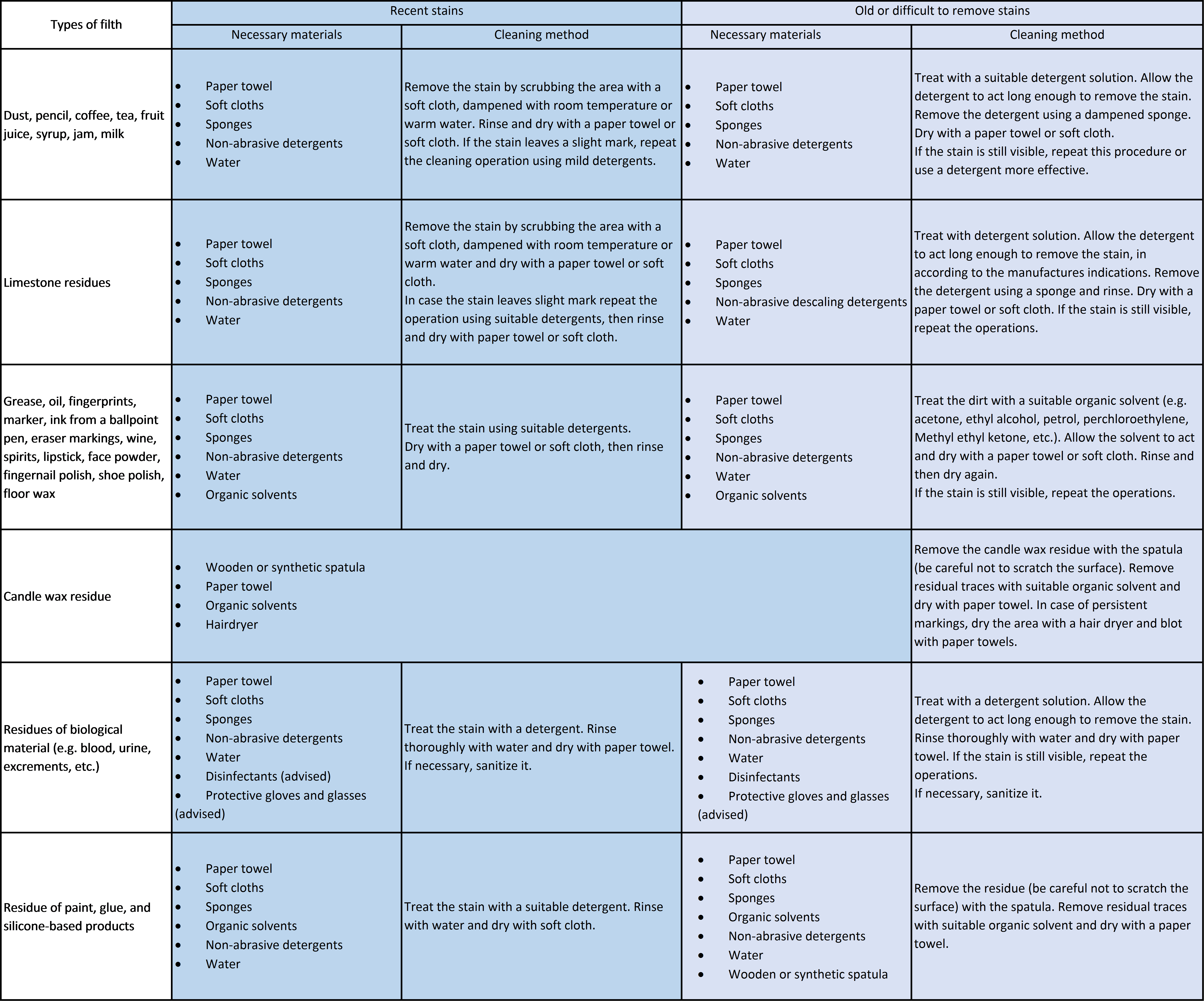

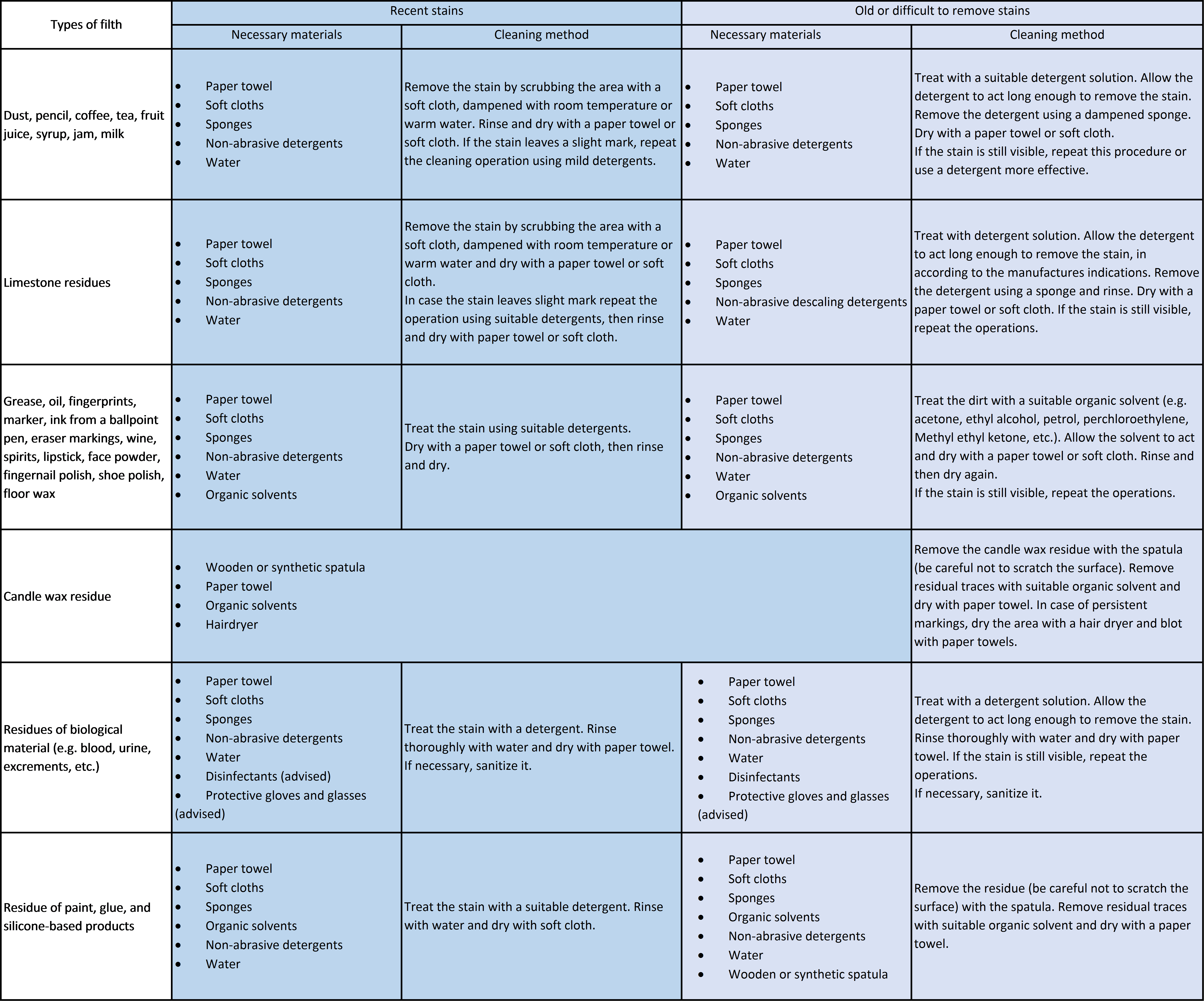

Cleaning and disinfection

For cleaning, use non-abrasive cleaning tools. Possibly avoid leaving dirt and stains for a long time on the surface of the laminate. To avoid leaving marks, always remove the detergent, rinse, and dry well. It is advisable to proceed with a preliminary test on a small portion of the surface. Do not use aggressive products (such as, but not limited to: muriatic acid, products for cleaning silver and caustic soda).

Accessories on demand

Upon request, it is possible to install an anti-X glass on the cabinet. The degree of protection of the glass will be the same as that of the cabinet. The fixing on the panel is done by means of a special silver-colored aluminum frame.